We offer both types of pneumatic conveying systems:

Dilute Phase Conveying Systems

Dilute Phase Pressure Conveying Systems transports bulk particles at low pressure and high velocity. The product to air ratio is low. The bulk particles are fully suspended in the conveying fluid (mostly air). These systems are commonly used for dry powders, granules that non fragile, non abrasive and have low bulk density. These systems are simple to operate, easy to install, cost effective and requires less headroom for bulk material conveying. These systems are ideal to convey material from multiple sources to single point in the processing.

Dilute Phase Conveying Systems are available in 3 designs:

1. Pressure Conveying Systems

Pressure conveying systems are best employed where the product is to be conveyed from one feeding point to several delivery points over long distances. Since the product has to be conveyed against the air pressure, locks or pressure vessels are required. Product delivery is under atmospheric pressure and however simpler.

2. Vacuum Conveying Systems

Vacuum pneumatic conveying systems are best employed where the product is to be conveyed from several feeding points to one delivery point. Product channeling is extremely simple and dust-free since there is no excess pressure

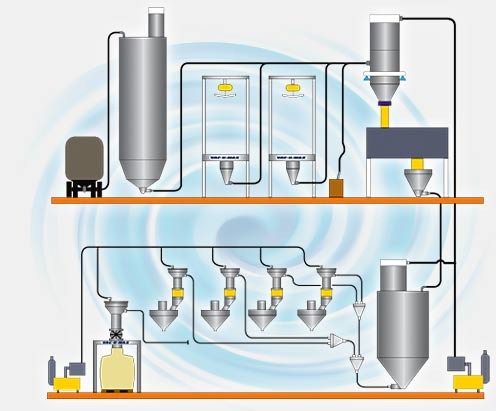

3. Combination of both – pressure and vacuum conveying systems

Conveying systems combining suction and pressure are best used where the product is to be conveyed from several feeding points to several delivery points.

Dense Phase Conveying Systems

In dense-phase conveying systems, bulk material is conveyed at a relatively low velocity and high pressure. The bulk particles are not suspended in air. The product to air ratio is high.

There are 2 types of dense phase conveying systems

1. Dense Phase Pressure Conveying

Dense-phase pressure conveying is suitable for gently conveying fragile or abrasive materials with particles 3⁄4inch and smaller over long distances (typically more than 250 feet). The system conveys material at a relatively low speed to reduce material degradation, air consumption, and abrasion on pipeline, bend, and diverter contact surfaces.

2. Dense-Phase Vacuum Conveying

Dense-phase vacuum conveying is ideal for gently conveying fragile or abrasive materials short distances (typically 200 feet or less). This system is typically used to transfer powder and granules at a low rate (25 tph or less) in applications such as truck or railcar unloading.